RUBBER SOLUTIONS FOR MEDICAL COMPONENTS MANUFACTURING >

PRODUCT CASE STUDY

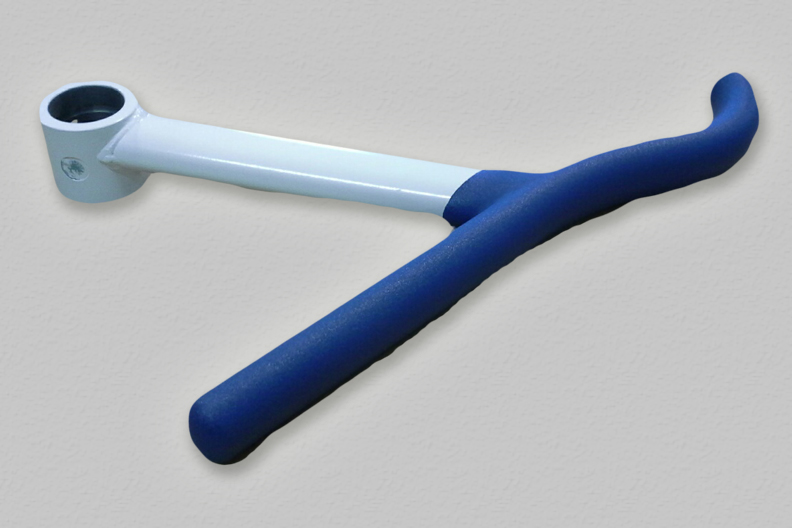

TRANSIT CHAIR ARMREST

CHALLENGE

Our customer needed to develop a transit chair armrest for a piece of equipment used to transport persons with disabilities. Touched by multiple hands in the course of its use, the armrests had to be soft and comfortable, yet easily sanitized.

SOLUTION

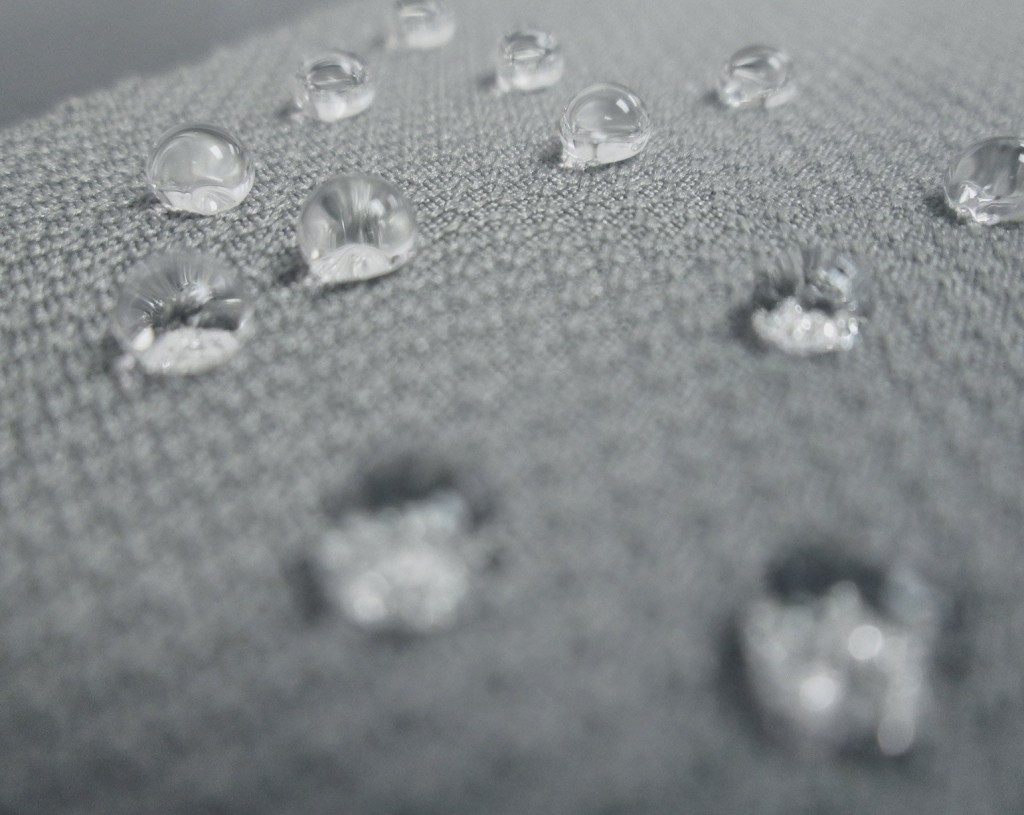

Midwest Rubber developed a specialized dip coating process to hermetically seal the armrests and other exposed areas of the equipment. Our process created a non-porous, yet soft surface. The resulting product was soft, comfortable, and practical, meeting our customer’s very specific manufacturing needs.

WHY MIDWEST RUBBER?

Antimicrobial

We keep the safety of our clients and their patients at the top of our mind. Exposed parts on medical equipment are touched by hundreds of hands every day. Unless the piece is cleaned after each contact, contaminants are able to multiply and create a safety hazard. We’ve solved this problem with the ability to mix our PVC products with an antimicrobial additive and hermetically seal them, making them resistant to bacteria. The antimicrobial handles and grips we produce are highly sought-after not only in the medical field, but across all industries.