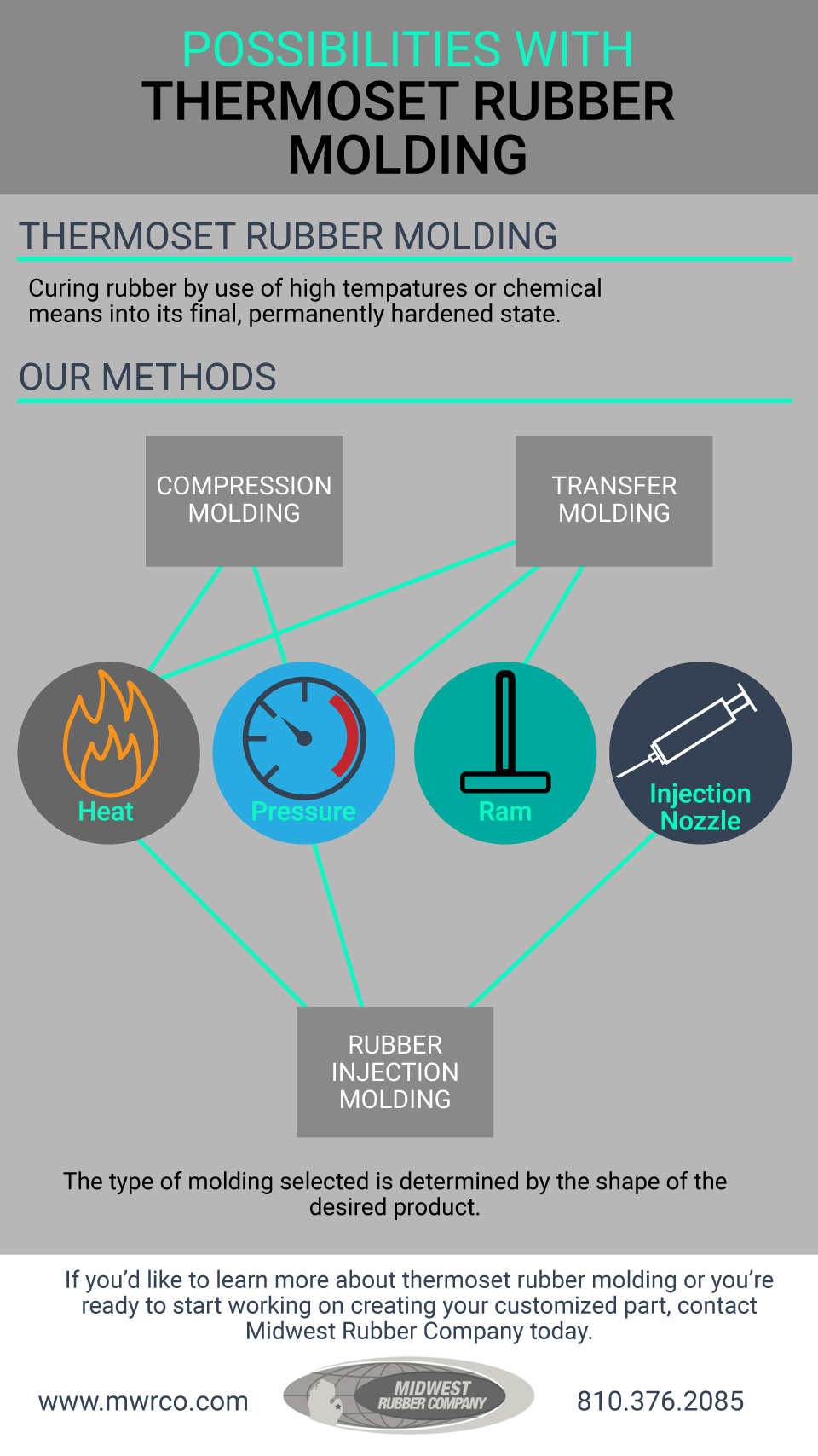

THERMOSET RUBBER MOLDING

Thermoset rubber molding comprises of several different techniques: compression molding, transfer molding, and injection molding. Each of these processes works by hardening, or curing, a soft piece of rubber into its final shape through the use of high temperatures or chemical means, which then becomes its permanent state. In compression molding, the material is heated and then pressed into its new shape. Transfer molding is similar, but also includes a ram that pushes the unformed material into its mold. Finally, with injection molding, heated, uncured rubber is pumped into a two-part cavity, which is then cooled and carefully pulled apart. Other businesses utilize injection molding with different materials, but at Midwest Rubber Company, we specialize in thermoset injection molded rubber, rather than plastic alternatives.

Thermoset rubber molding offers the following advantages:

- Durability. Objects produced using thermoset molding are permanently solidified and cannot be broken down.

- Strength. During the manufacturing process, thermoset-molded items will be subjected to heat and pressure. The finished goods maintain the strength needed to withstand these conditions.

- Precision. Forms used in thermoset rubber molding must be meticulously built, giving you a fine level of control over their structure.

Many different kinds of products are created with thermoset rubber molding. Here are some examples:

- Rubber boots

- Automotive components

- Toys

If you’re in need of a custom-made part for your project, thermoset rubber molding could be the right choice for you. Contact us and we can start discussing how to put your idea into action.