SOLUTIONS BY INDUSTRY

RUBBER SOLUTIONS FOR MEDICAL COMPONENTS MANUFACTURING

Midwest Rubber is proud to support medical professionals in their vital work. We create solutions that help keep their patients comfortable and secure.

OUR MEDICAL COMPONENTS MANUFACTURING START

We first began manufacturing blood pressure cuff inflator bulbs more than 60 years ago. Since then, we’ve significantly expanded our work in the medical field. Although we were once best known for our automotive parts creation, the number of healthcare industry projects we’ve added to our repertoire in recent years has caused medical components manufacturing to become the largest facet of our business today. We offer a lineup of highly specialized products that includes medical pads, cushions, armrests, headrests, hospital bed accessories, diagnostic equipment, emergency kits, gurneys, and stretchers. We also have the engineering prowess to design entirely new parts if your project is outside the scope of traditional applications. With decades of experience in the medical industry and a variety of manufacturing processes to choose from, our medical components offer both value and quality.

MEDICAL COMPONENTS MANUFACTURING EXPERTISE

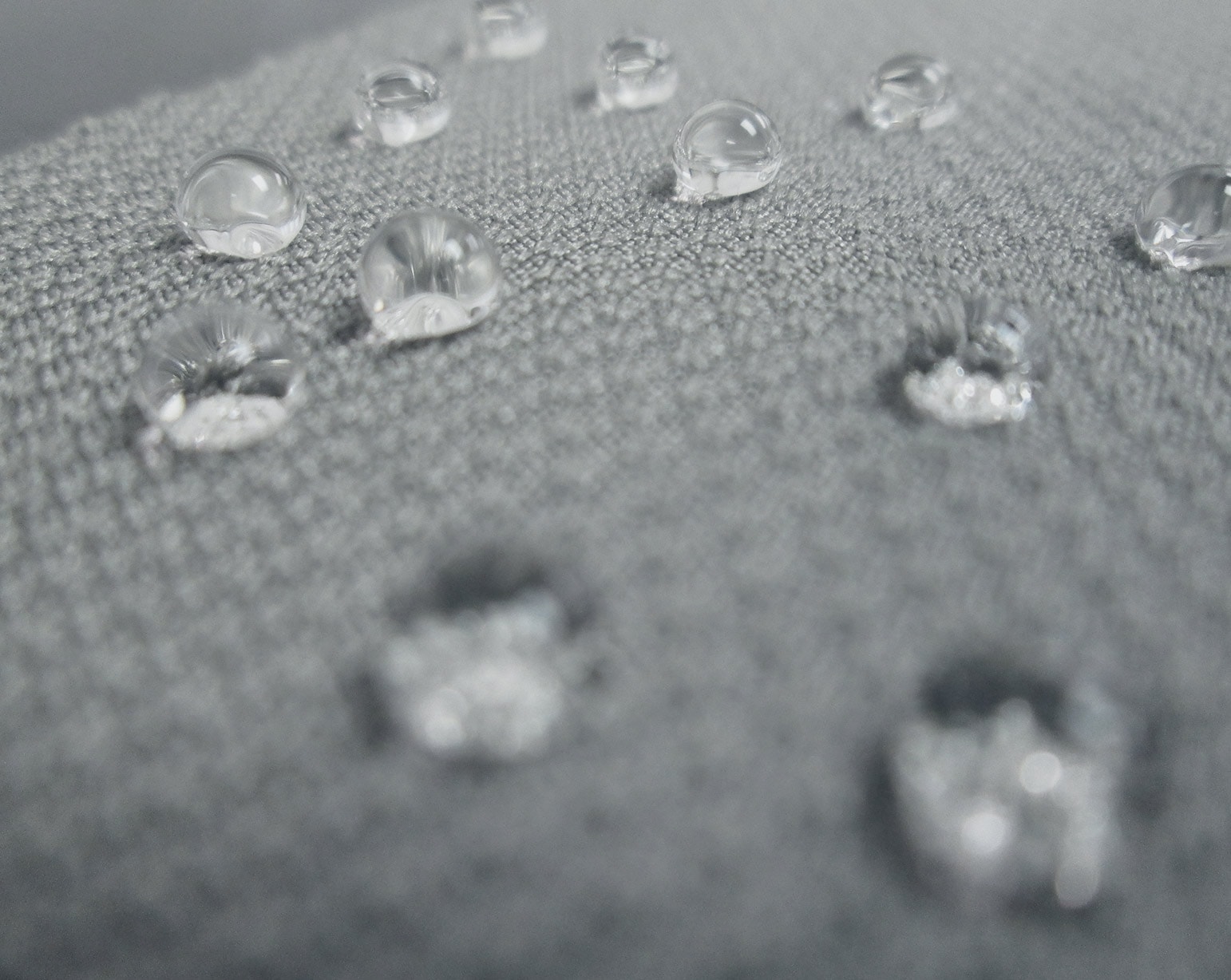

As experts in rubber processing, Midwest Rubber can create custom solutions for healthcare products as well as help bring inventions into the market. We’ve devised unique medical pads for wheelchair application, custom hip supports, and cushionsdesigned to accommodate a complex set of our customers’ needs. We understand that safety is a major factor when it comes to medical components manufacturing, and we take pride in providing parts that limit potential risks and are easy to disinfect. For some applications we are even able to use an antimicrobial additive to the material chosen for the job to prevent bacteria from growing. We know that reducing nosocomial (or hospital-acquired) infections is a goal for the entire medical community, and we’re focused on aiding in that effort from a design standpoint.

Additionally, we have experience working with many other materials depending on what your product demands. We have developed several polyvinyl coating (PVC) dipped solutions for common healthcare problems, such as hooks and clips to prevent the noisy clanging of metal instruments on moving carts and bumpers for the wheels of hospital beds. We are also skilled at urethane foam molding, which can create contoured and comfortable cushions that can be used for a variety of medical applications. One of our most demanded applications of this process is the development of calf rests for delivery rooms. These rests are thoughtfully designed to provide stability and support to the user while also being cushioned enough to add comfort for a mother in labor. We put practicality at the forefront of design, which leads to long-lasting and desirable products.

On top of being able to design different shapes for medical parts, we are also able to customize the color and finish to create the piece exactly as you imagined it. Several of our past clients have expressed satisfaction with being able to color code pieces based on where they would be used. No matter the healthcare project you are trying to tackle, we’re able to provide our expertise on how to accomplish the desired final product, and the possibilities are endless. We are aware of the importance of communication when it comes to determining specifications for each product, and we always work with our customers to ensure we execute their ideas accurately.

QUALITY HEALTHCARE PRODUCTS

In the healthcare industry, quality isn’t just desired, it’s mandatory. Every component that a patient or healthcare practitioner comes in contact with needs to meet certain standards. At Midwest Rubber, we believe it’s our obligation to provide products that are dependable and safe. Whether it’s handle grips for a transport chair or the padding used inside it to protect the integrity of a patient’s skin, we know that every component is a crucial element in the overall picture. We manufacture equipment we know professionals will feel confident in and that their patients will find easy to use. We’re delighted to have been selected as the supplier for many different products in the medical field over the years because we truly enjoy empowering the individuals who perform this critical work.

Our ability to create custom pieces exceeds most other medical components manufacturing companies because of the diverse range of processes we can offer in one facility. We are able to accommodate even the most stringent specifications by blending multiple processes to develop a part that can be dynamically different from the inside to the outside. Our head support cushions are an excellent example of how we were able to produce a piece of equipment within customer specifications by taking an innovative approach to designing the part. We were able to create a design that was not only comfortable for the patient that would be using it, but also suitable for stabilizing the head for tests that require no movement. When you work with Midwest Rubber, you can be positive that our experience will show in every component we create on your behalf.

We are dedicated to producing the highest quality of work for a field that demands nothing but the best. Our team of highly qualified engineers and staff members recognize the significance of quality assurance. This is why we are meticulous about testing our products at every stage of development, not just upon completion when errors could be more costly to correct, in order to produce components that live up to not only our clients’ expectations, but ours as well. We know having high quality products is imperative to maintaining a good reputation, so we ensure that every part we deliver will satisfy our customers and their end-users completely. This practice has led us to a number of repeat customers and referrals from past clients, which we are always delighted to get.

CONTACT MIDWEST RUBBER TODAY

Do you have a healthcare product challenge that you need a solution for? Whether you have a new product, need a new supplier for a current part, or want to explore the possibility of making your component even better than it is now, Midwest Rubber can help. We enjoy taking on new challenges and finding answers that others couldn’t imagine. Feel free to contact us to see how we can put our medical components manufacturing background to work for you.

WHY MIDWEST RUBBER?

Antimicrobial

We keep the safety of our clients and their patients at the top of our mind. Exposed parts on medical equipment are touched by hundreds of hands every day. Unless the piece is cleaned after each contact, contaminants are able to multiply and create a safety hazard. We’ve solved this problem with the ability to mix our PVC products with an antimicrobial additive and hermetically seal them, making them resistant to bacteria. The antimicrobial handles and grips we produce are highly sought-after not only in the medical field, but across all industries.