AUTOMOTIVE PARTS MANUFACTURER >

PRODUCT CASE STUDY

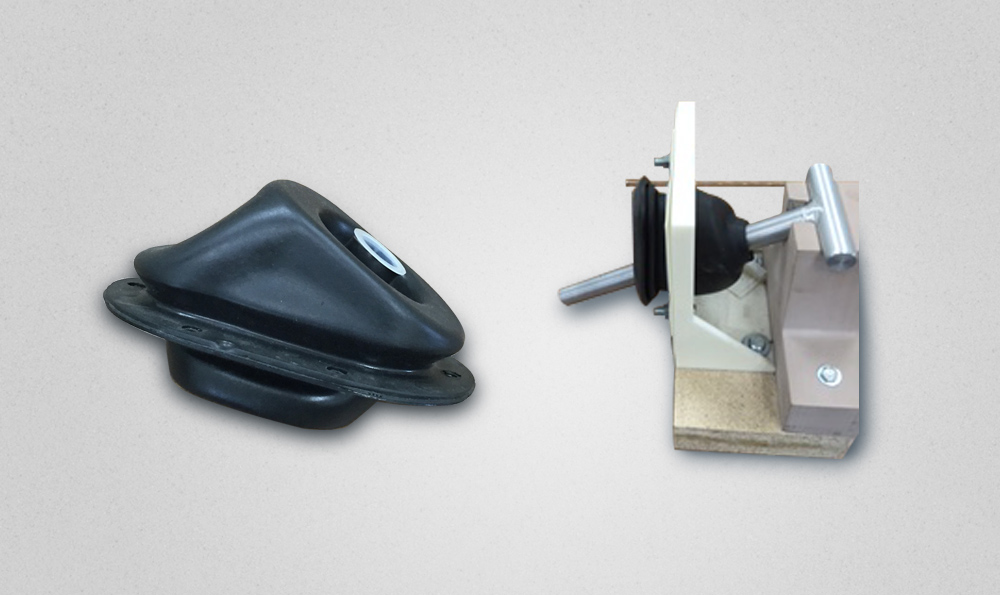

STEERING COLUMN SEALS

CHALLENGE

For many years, Midwest Rubber has supplied steering column seals for cars and trucks. More recently, weight reduction goals, higher heat in the engine compartment, and ease of installation for the assembly have made it increasingly difficult to compete. In one recent program, Midwest Rubber was asked to create a seal that would allow the steering shaft to be raised into an acute angle while the seal remained locked into place.

SOLUTION

Our engineering team developed an adaptable seal, created of molded or dipped rubber, that was able to meet increasingly stringent assembly requirements and helped our customer remain competitive in an ever-changing environment. The final steering column seal provided the flexibility our customer required, and eliminated two previous components from the assembly process. The complexity and weight was reduced, and the assembly process was simplified.

WHY MIDWEST RUBBER?

Vibration

Our solutions ensure less noise and a longer service life. Midwest Rubber strives to do everything we can to simplify your operations, and this includes reducing and eliminating excessive vibration caused by machinery. Noise vibration harshness can be caused by any type of motor, and can be a huge source of stress and disruption – not just to the machine, but to you as well. We create our solutions using custom molded rubber and rubber-to-metal bonded parts, making them a premium solution for anti-vibration.