AUTOMOTIVE PARTS MANUFACTURER >

PRODUCT CASE STUDY

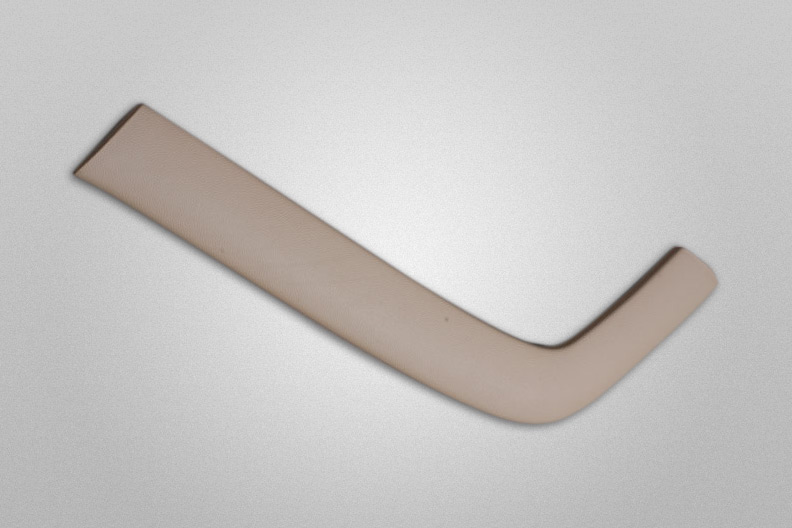

LEG REST

CHALLENGE

A customer was experiencing breakage in the field on an interior automotive trim component. The leg rest component was constructed of a hard plastic substrate with leather look skin, and polyurethane foam cushion formed in between the two. The substrate had molded tabs located at intervals to accommodate fastener clips used for lock-in retention. The tabs were consistently breaking off in the field, often even before the vehicle left the showroom.

SOLUTION

The Midwest Rubber engineering team performed a detailed analysis and investigation of the broken tabs. We soon realized the substrates, made using a polycarbonate blend, were easily weakened after being processed too quickly at too high a temperature. However, the resulting problem was not becoming apparent until a week later, making detection difficult. After we changed the substrate supplier to one who used a different process, no further failures occurred. Our customer appreciated our careful analysis of every step of the production process to identify the problem and successful solution.

WHY MIDWEST RUBBER?

Vibration

Our solutions ensure less noise and a longer service life. Midwest Rubber strives to do everything we can to simplify your operations, and this includes reducing and eliminating excessive vibration caused by machinery. Noise vibration harshness can be caused by any type of motor, and can be a huge source of stress and disruption – not just to the machine, but to you as well. We create our solutions using custom molded rubber and rubber-to-metal bonded parts, making them a premium solution for anti-vibration.