This blog will spotlight another one of our processes; this time, we will be looking at thermoset rubber molding. To see all our blogs, visit our news archive and stay up-to-date on what’s happening at Midwest Rubber Company.

Thermoset rubber molding is a process that takes a monomer and transforms it into a polymer, which provides stability and heat resistance. We have three methods of performing thermoset rubber molding – compression molding, transfer molding, and injection molding; each technique is more complex than the last. The type of molding selected is determined by the shape of the desired product. Unlike thermoplastics, thermosets cannot be melted down and reworked by heat. The process is permanent, which makes it more desirable for products that need to be durable.

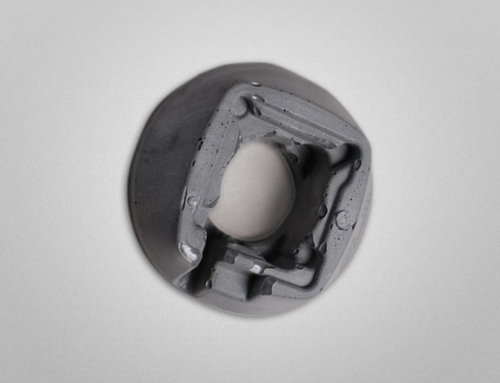

Compression molding uses heat and pressure to form a part. A two-piece form is used to compress the chosen material into the desired shape. Any surplus material that escapes from the sides of the mold is trimmed off in the finishing process. Transfer molding adds a third piece to the form, which works as a plunger to push the material down into the heated form. Injection molding utilizes a two-part form into which heated liquid material is injected. The cavity is filled at a high pressure so that the entire space is filled and the object will look exactly as the cavity was designed. For all types of thermoset molding, the forms are left together until they have cooled completely; then, they can be safely pulled apart to remove the resulting object.

In thermoset rubber molding, the integrity of the form is paramount. Because it will be continually subjected to the intensive process of being heated and cooled, the form must be strong enough to withstand this harsh treatment. That’s why forms for thermoset rubber molding must be made of high-quality metal that has been machined into the desired shape. Building these forms can be expensive, so Midwest Rubber always tests them extensively to make sure they’re up to standard.

At Midwest Rubber Company, we use our extensive knowledge of thermoset rubber molding techniques to create the desired product at the best price possible based on client needs. We spend a lot of time working with our customers to make sure their expectations are fully satisfied and the design we’ve created together meets the goal for their particular project.

If you’d like to learn more about thermoset rubber molding or you’re ready to start working on creating your customized part, contact Midwest Rubber Company today.