How to Find the Best Manufacturer for Your Medical Product Lines

When choosing the right manufacturer for your product, the stakes are often high. This can be especially true for parts and components produced for the medical industry. You’ll likely have plenty of questions. Which process is right for your product? What kind of quality assurance can the manufacturer offer you? What experience and success does the manufacturer have in your industry? A thorough understanding of these issues can help you choose the right manufacturing partner for your project.

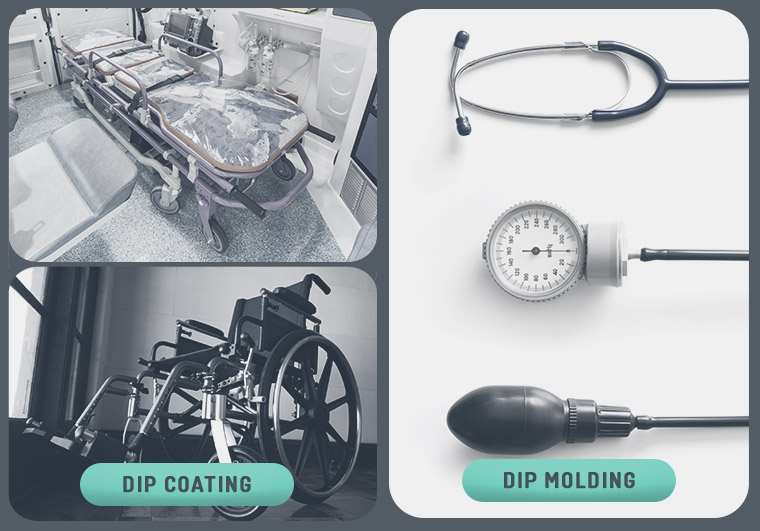

Dip coating or dip molding? That is the question.

Dip coating and dip molding are two processes commonly used to manufacture parts for the medical industry. In the medical dip coating process, a part is heated, dipped into a coating material, and heated again to set and permanently adhere the coating to the part underneath. Medical dip molding is the process of dipping a metal form (or tool) into a liquid material such as PVC, neoprene, or polyurethane to create an elastomer or rubber part. For products developed for the medical industry, the coating or part will likely include antimicrobial additives to ensure it can withstand repeated cleaning with the harshest detergents.

Each of these process offer a number of benefits:

Dip coating process benefits:

- Lower production runs are possible.

- Dip coating is cost effective, and offers quick turnaround time.

- Dip coated products are available in a range of colors and finishes, can be branded with a logo, and are suitable for a wide range of applications.

- Coatings can be modified for thickness and to accommodate a range of geometric shapes.

Dip molding process benefits:

- The tooling used is generally less expensive than other processes, which means both long and short production runs can be quite cost-effective.

- Dip molded parts can be quickly produced, another reason this process is excellent for high-volume runs.

- This process can produce extremely thin-walled parts and works for both expandable rubber material and inflexible material, such as PVC.

- Final results are highly consistent.

Quality is critical

The highly-specialized requirements and regulations of the medical industry demand the most stringent of manufacturing practices. It’s important to have a solid understanding of a number of factors when considering a manufacturer for your device, part or component:

- What kinds of quality assurance and quality control programs does the manufacturer have in place? They should be able to explain their entire process to you.

- Does the manufacturer have a defined set of quality standards for each of their products?

- How is the manufacturer able to foresee potential challenges and avoid pitfalls down the line?

- What kind of authority do the people on the production line have? If they see a problem, are they empowered to stop production? If the answer is no, you may want to keep looking.

- What kinds of focus exists for continuous improvement in order to keep or even help set the pace for the industry?

The manufacturer you are considering should be able to speak extensively to each of these questions, and should also be asking you a number of questions to demonstrate their intention to understand the entire scope of what you want and need out of your final product.

If you’d like to learn more or have questions about the best manufacturing process for your medical product lines, please reach out to one of our engineers. We would love the opportunity to discuss your project.