RUBBER SOLUTIONS FOR MEDICAL COMPONENTS MANUFACTURING >

PRODUCT CASE STUDY

HEAD SUPPORT CUSHION

CHALLENGE

A medical supplier approached Midwest Rubber to manufacture a hermetically-sealed cushion to comfortably, but securely, hold a patient’s head steady during highly sensitive diagnostic neck scans, such as MRI and CAT scan procedures. The head support cushion could not contain holes or other voids that would weaken security and compromise the patient’s medical test. The cushion must be specially coated for proper antiseptic cleaning, be unable to peel or lift, and have zero surface blemishes.

SOLUTION

Midwest Rubber engineers developed two customized materials for both the core and surface components of the cushion. The processes were unique in application, but Midwest Rubber was able to marry the two components successfully with our foam molding process. The result was 100% client satisfaction. This very popular cushion design is currently manufactured and supplied to hospitals and diagnostic labs throughout North America.

WHY MIDWEST RUBBER?

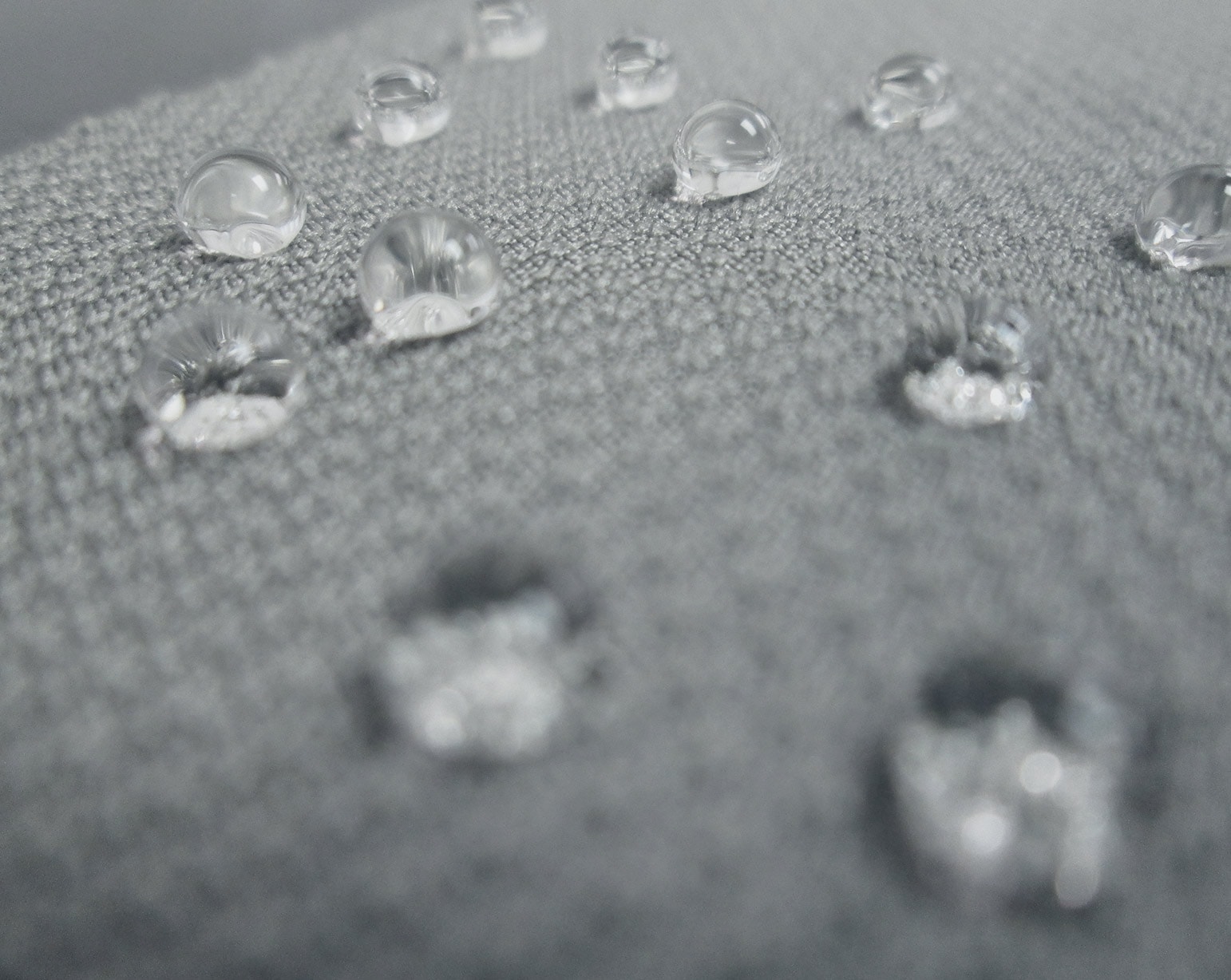

Antimicrobial

We keep the safety of our clients and their patients at the top of our mind. Exposed parts on medical equipment are touched by hundreds of hands every day. Unless the piece is cleaned after each contact, contaminants are able to multiply and create a safety hazard. We’ve solved this problem with the ability to mix our PVC products with an antimicrobial additive and hermetically seal them, making them resistant to bacteria. The antimicrobial handles and grips we produce are highly sought-after not only in the medical field, but across all industries.