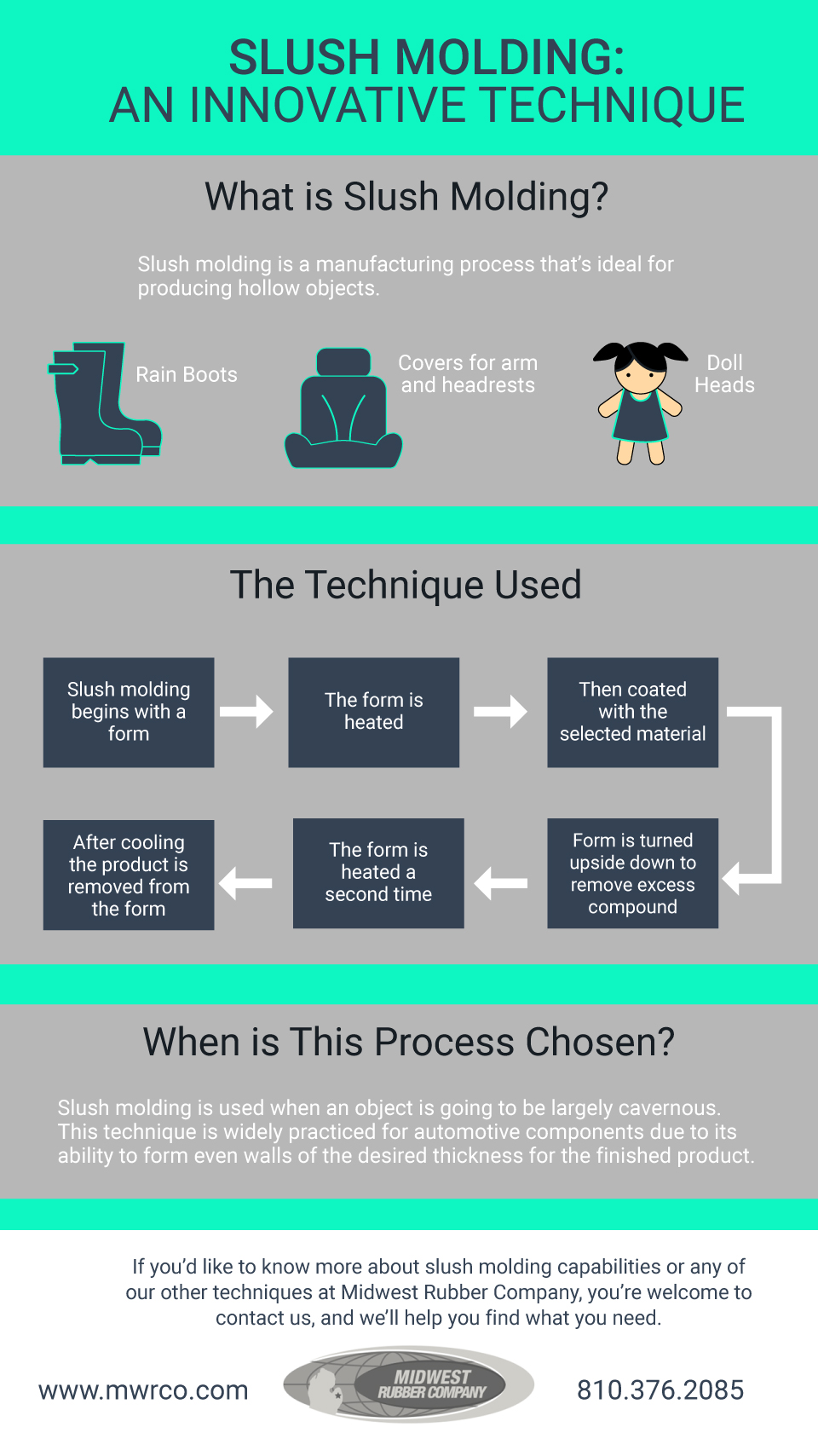

SLUSH MOLDING

When a client needs a part with a cavity, we often turn to slush molding. It’s a process that can be used to create products meant for end consumer use, like shoes and toys, but it is also suitable for automotive components. We start off by working with our client to design the right model that will meet the specific needs of their project. A form to be used in slush molding will be hollow so that the resulting item is also hollow. We heat the form up, then fill it with the material we chose for the job, often plastisol. At this point, an inner layer is established, but is still soft. The form is inverted to remove excess material and then heated again, which solidifies the part. After cooling, the item is removed and considered finished.

There are several advantages to slush molding that make it a valuable technique:

- Versatility. For simple projects, slush molding can be done entirely by hand but may also be accomplished through automated means.

- Applicability. Slush molding can be used to make hollow objects for many different industries and meet a variety of different needs.

- Simplicity. Slush molding has relatively few steps, making it easy to understand and execute.

Because hollow objects of some kind are needed in just about every field, there are many industries where slush molding is utilized. Here are some examples of products that Midwest Rubber Company has manufactured with slush molding:

- Protective coatings for arm rests in vehicles

- Instrument panels

- Containers

Do you have any questions about slush molding? Or are you in need of a custom slush-molded part for your project? Contact us now and we’ll get you the right answers.